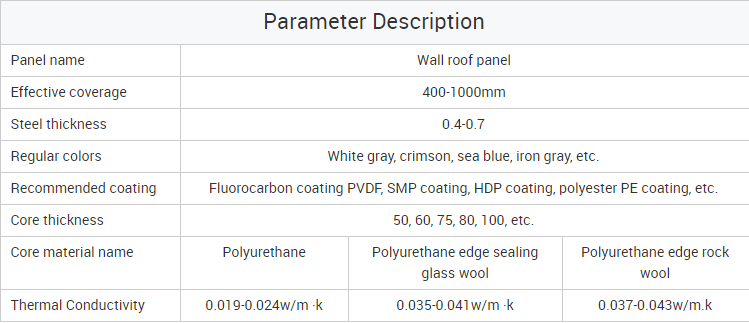

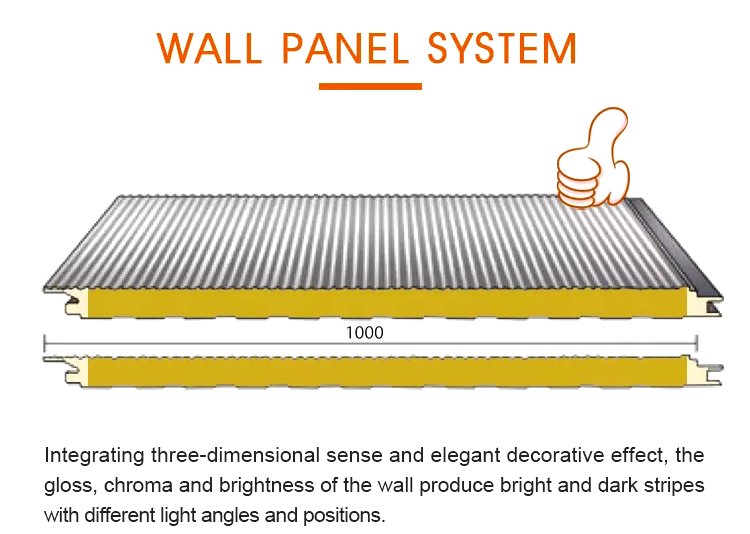

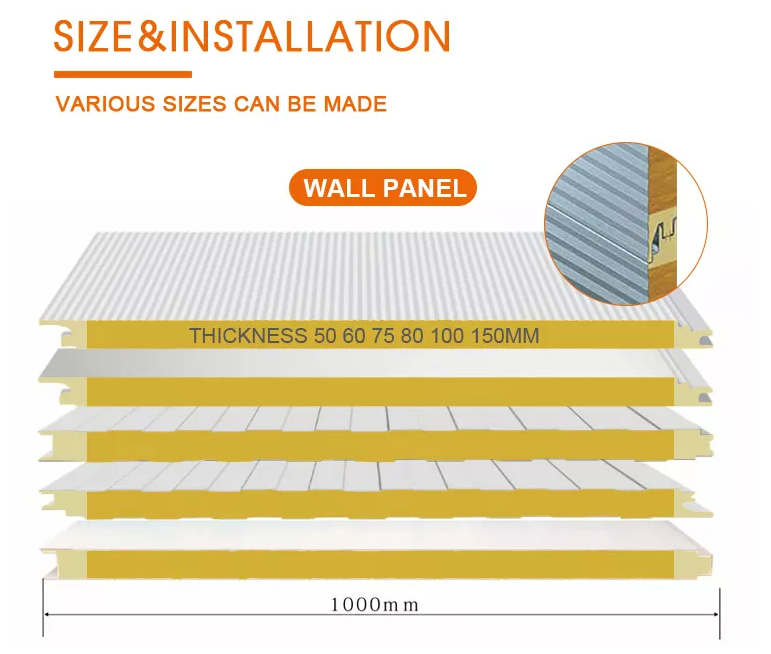

The rock wool composite board adopts high-quality color-coated steel plate as the panel, the core material is basalt as the main raw material,

and the inorganic fiber board is made of rock wool and glass wool raw materials through high temperature melting, and it is formed by double-

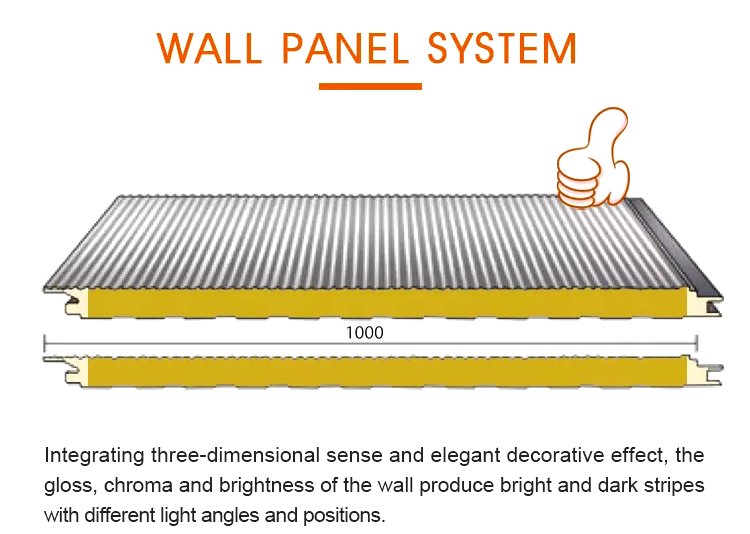

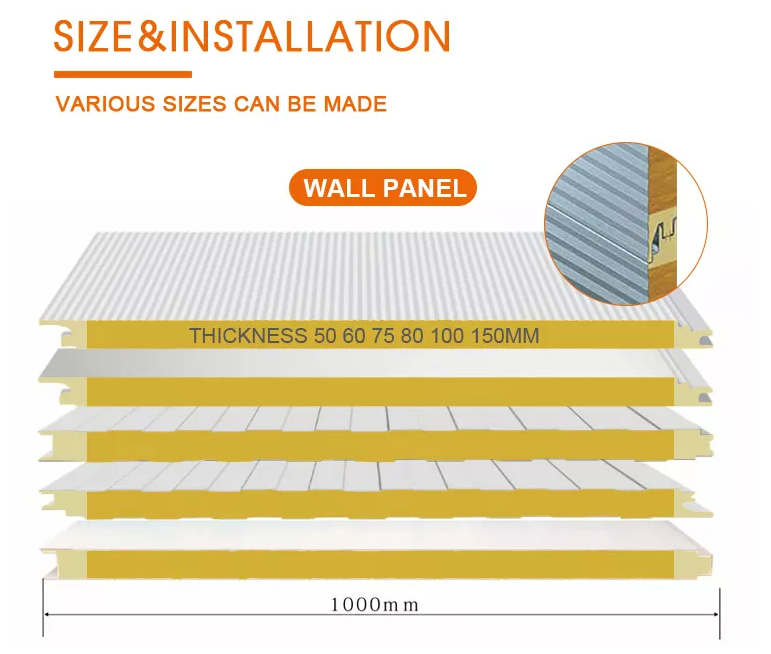

track controllable molding. It has excellent thermal insulation properties and ideal flexural properties. It has the characteristics of light weight,

small thermal conductivity, heat absorption, non-combustibility, sound insulation, high strength, smooth surface, and novel plate shape, which

reduces the thickness of the envelope structure to a certain extent and increases the clear space of the building.

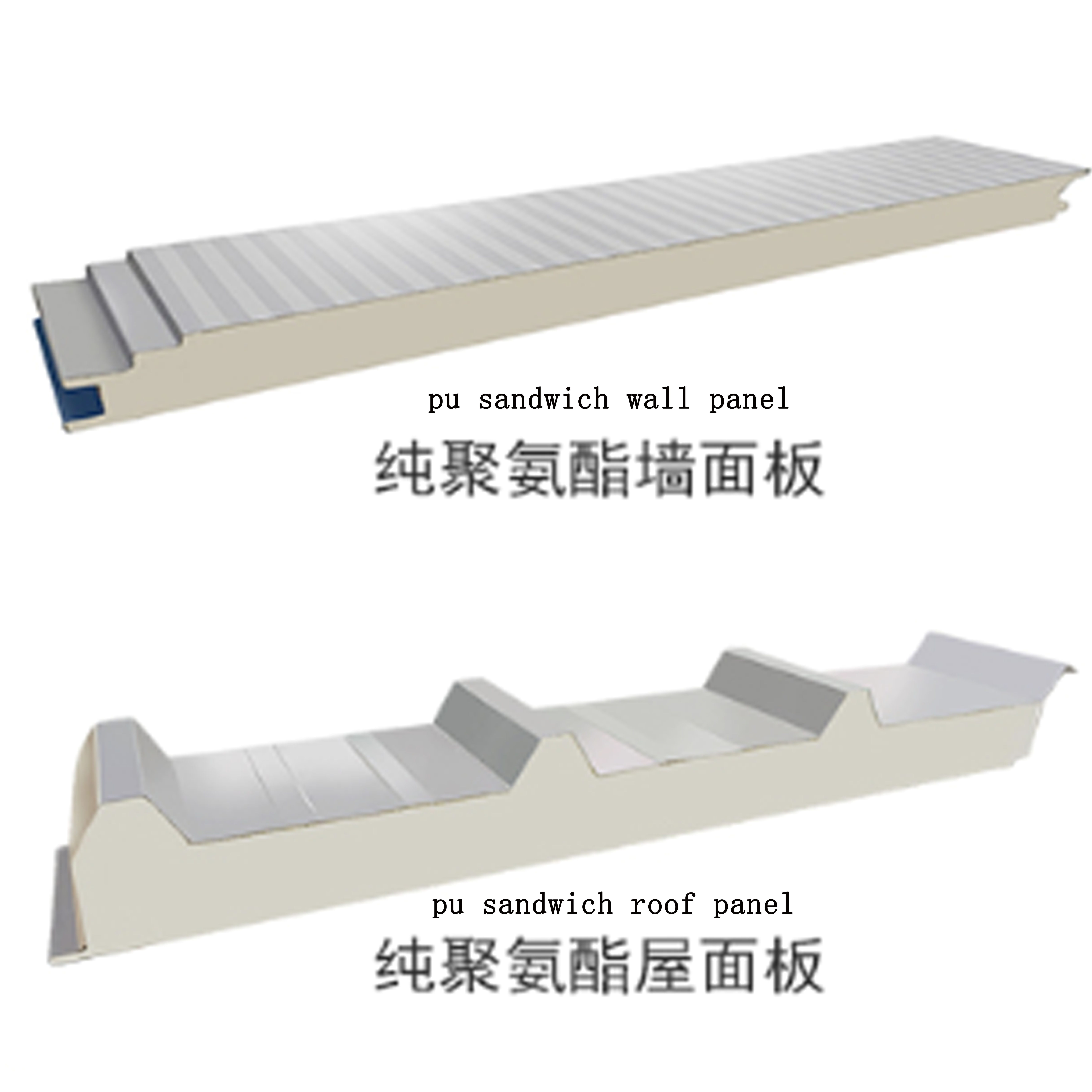

PU-wrapped rock wool insulation panel: Polyurethane material edging reasonably avoids the exposure of the rock wool

board—General rock wool insulation board: No urethane material edging causes the rock wool panel to be exposed.

Advantage:

Water-tightness/air-tightness: Polyurethane is used to seal the edges, and the tongue and mouth are flat and can effectively prevent the

intrusion of water; the end connection of the board is sealed inside to maintain good tightness.

Rugged and durable:Use high-quality rock wool or glass wool, with high water repellency and long-lasting stability. Beautiful facade:

screw hidden joint design, high flatness of the board surface, rich paint coating color, and long-lasting color.

Airtight sound insulation : good sound absorption, it can reduce the sound caused by the impact of rain, hail, etc. Corrosion resistance :

aluminum foil can be used instead of color steel plate to improve the high temperature resistance and corrosion resistance of the product.

Previous:

Factory Outlets China Home Decorative Fireproof Ceiling Board PU Sandwich Panel

Next:

Generous and beautiful rock wool sandwich board for exterior wall