Fireproof/waterproof rock wool manufacturer sandwich panel for the roof and wall

The formed plate has excellent characteristics of fire prevention, thermal insulation and environmental protection, which provides a good choice for the enclosure system of industrial buildings

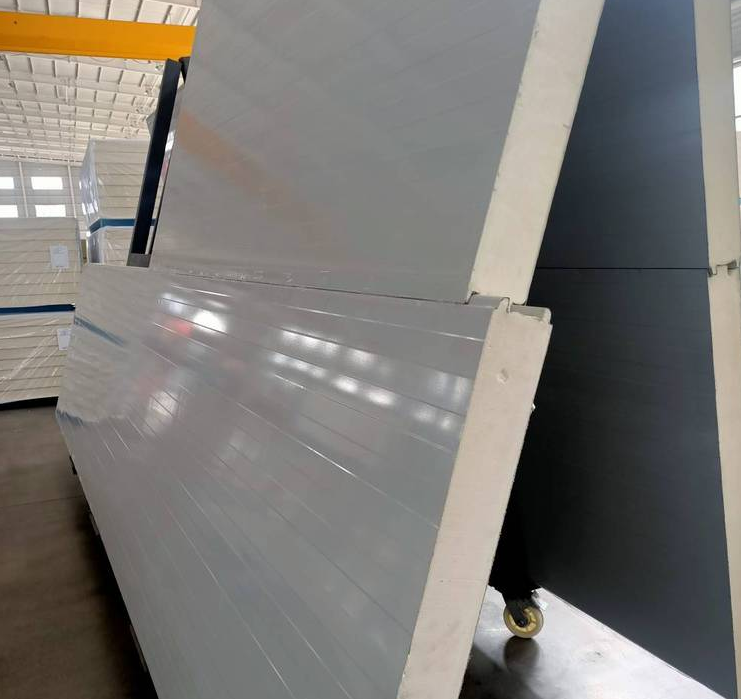

Connection mode:panel is connected to the purlin by self tapping screws, and the other part is lap joint

| Product name |

PU Edge sealing rock wool /Glass wool sandwich Panel for roof |

| Suface material | color steel sheet/aluminum foil |

| Steel thickness | 0.3-0.8mm |

| Core material | PU Edge sealing + rock wool/Glass wool core |

| Core thickness | 40mm,50mm,75mm,100mm,150mm,200mm |

| Effective width | 1000mm-1130mm |

| Length | Customized(the max 11.8m) |

| Color | Ral color |

| Zinc content | AZ40-275g/m2 |

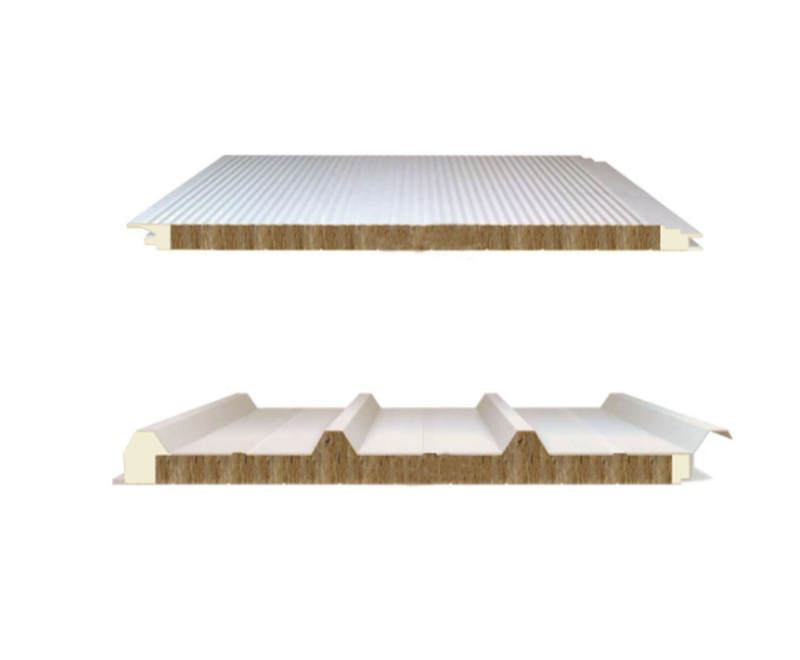

| Wave | three waves or four waves (36mm、45mm) |

| Advantages | Lightweight/Fireproof/Waterproof/Easy Install/Insulation |

| Surface Appearance | seamless-wave/slitwidth-wave/concave-wave/Flat/Embossed/Other |

| Usage | It is suitable for the various roofs and walls referring to the large-size factory buildings, storage, exhibition halls, gymnasiums, freezing stores, purification workshops, etc. |

Polyurethane edge sealing Rock wool/Glass wool composite board is a high-quality energy-saving building board formed by the interaction of non combustible structural Rock wool/Glass wool as the core material, galvanized or aluminized zinc color coated steel plate as the finish, polyurethane edge sealing at both ends and professional developed adhesive. It integrates fire prevention, thermal insulation, noise isolation and beautiful decoration.

Main features

1.select (suitable) material:

High quality structural rock wool/glass wool is selected. Rock wool is made of natural rocks and minerals. It has high hydrophobicity, low slag ball content, no asbestos and no mold.

The metal panel is made of high quality galvanized or coloured zinc coated steel sheet. It has excellent anticorrosive and anti-aging properties and excellent adhesion.

2.Technology:

The new production technology of rock wool/glass wool turning 90 degrees is adopted to make it perpendicular to the steel plate, which greatly improves the compressive strength. The new rock wool composite board can adopt polyurethane edge sealing to ensure good air tightness and water tightness.

The adhesive is distributed by spraying, and the use amount is three times that of conventional products, which greatly increases the bonding strength.

3.finished product:

The polyurethane edge sealing rock wool/glass wool composite board is a structural rock wool/glass wool in the middle, and there are 50mm wide polyurethane insulation materials from both sides to the end. It can also be made into a composite board filled with rock wool/glass wool.