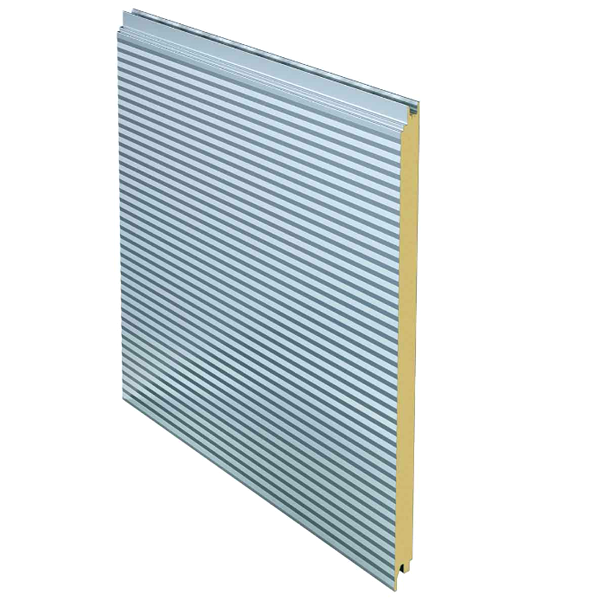

Hot Sale Manufacture Top Quality 50/75/100mm PU Sandwich Panel

As a new material in structure, the polyurethane roof panel has been the most suitable choice for many users.

wall & roof system

| Type | PU sandwich roof panel/polyurethane sandwich wall or roof panel |

| Core | polyurethane |

| Density | 40-45kg/m3 |

| Surface material | color steel sheet/aluminum foil |

| Steel thickness | 0.3-0.8mm |

| Core thickness | 40/50/75/90/100/120/150/200mm |

| Length | 1-11.8m |

| Effective Width | 1000mm |

| Fire Rating | Great B |

| Color | Any Ral color |

| Wave-for roof | three waves or four waves (36mm、45mm) |

| Advantages | Lightweight/Fireproof/Waterproof/Easy Install/Insulation |

| Surface Appearance | seamless-wave/slitwidth-wave/concave-wave/Flat/Embossed/Other |

| Usage | It is suitable for the various buildings referring to the large-size factory buildings, storage, exhibition halls, gymnasiums, freezing stores, purification workshops, etc. |

Material instruction

1)Suface sheet:

Usually the surface sheet of PUR or PIR sandwich panels is PPGI or PPGL steel color coated sheets.PPGI is prepainted galvanized coated steel and PPGL is prepainted Al-Zn coated steel.For coating type,you could choose PE, PVDF, HDP, SMP,ect.Our strategic cooperation brands are Bluescope, Bao-steel, Shougang steel, Guanzhou steel, Yieh Phui steel,Xinyu steel,etc.

2)Polyurethane core material:Our polyurethane core material strategic cooperation brands are D·BASF, Huntsman, WANHUA, etc.

Features

Pre engineered for precision and simple construction.

Pre painted galvanized sheets.

Sandwich panels are extremely light weight

High structural rigidity and reliability.

Prefab Sandwich panel of various heights available

Heat, Sound and water insulated.

Fire and impact resistant.

Energy efficient.

Low energy consuming.